Embroidered patches are a great way to add a personal touch to your clothing or accessories.

However, Creating patches seems a mystery for some people. Luckily, with the right tools and techniques, it will be easy to create custom patches.

I. What are the Types of Custom Embroidered Patches?

If you’re in the market for custom patches, one of the decisions you’ll need to make is what type of patch backing to choose. There are multiple patch backings available, each with its own advantages and disadvantages. Now, we’ll break down the most popular patch backings.

Categorizing Patches by Backings: which backing to choose?

1. Sew on Backing

The sew-on backing is the most traditional method of attaching a patch to a garment. This type of backing is ideal for patches that will be attached permanently to a uniform or sports team jacket. Sewing on a patch ensures that it won’t come loose, even after multiple items of washing. If you’re looking for a classic, durable patch option, sew-on backing is the way to go.

2. Iron-On (Heat Seal) Backing

Iron-on, also known as heat seal, is a popular option for those who want a quick and easy way to attach a patch to a garment. This backing requires heat and pressure to bond the patch to the fabric. It’s important to note that iron-on patches are not as permanent as sew-on patches for big patches.

3. Peel and Stick (Hook and Loop) Backing

Peel and stick backing, also known as hook and loop, is a popular choice for those who need an on-off patch. This type of backing allows you to easily remove and reattach the patch as needed.

Peel and stick patches are often used by military personnel for tactical purposes.

4. Adhesive Backing

The adhesive backing is a great option for those who want a strong bond without the need for sewing or ironing. This type of backing is ideal for patches that will be attached to a non-fabric surface, such as a car or a laptop. Adhesive patches are also great for temporary use. Keep in mind that adhesive patches are one-time patches. may not be as durable as sew-on patches.

5. Safety Pin Backing

Safety pin backing is a popular option for those who want a quick and easy way to attach a patch to a garment. This type of backing is ideal for those who want to switch out patches frequently.

6. Magnet Backing

Magnet backing is a popular choice for those who want a temporary way to attach a patch to a garment. This type of backing is ideal for those who want to switch out patches frequently or for those who don’t want to make any permanent modifications to their clothing.

7. Paper Backing

Paper backing is paper on the back of a custom embroidered patch. smooth surface and clean. just a need a little extra cost. the kind of patches needs to sew on.

Choosing the right patch backing depends on your specific needs. If you’re looking for a permanent solution, sew-on backing is the way to go. If you want a quick and easy option, iron-on or adhesive backing are your go to.

II. How to make custom patches?

In this part, Let’s go through the step-by-step process of making your own custom patch. From designing your own patches patch to stitching it onto your favorite item.

How to make custom patches?–Part 1: Designing Your Patch

The first step in making your own custom embroidery patch is designing the patch itself. Here are the steps you should follow to create a design:

Step 1: Choose Your Design Software

To create a digital design for your patch, you’ll need to use design software. Some popular options include Adobe Illustrator, CorelDRAW, and Inkscape. These programs are specifically designed for creating vector-based graphics, which are necessary for creating embroidery designs.

Step 2: Create Your Design

Once you have your design software, it’s time to create your patch design. You can start with a sketch or an existing image and use the software’s tools to create a vector-based version of the design. Make sure to keep the design simple, with clear lines and minimal shading, to make it easier to translate into an embroidery design.

Step 3: Convert Your Design to an Embroidery File

After you’ve created your design, you’ll need to convert it to an embroidery file format. There are many different file formats used in embroidery software but some of the most common include DST, PES, and JEF. You can use software like Embird or Wilcom to convert your design to the correct file format.

Part 2: Creating Your Patch

Now that you have your design in embroidery file format, it’s time to create your patch. Here are the steps you should follow to turn your digital design into a physical embroidery patch:

Step 1: Choose Your Fabric

The first step in creating your patch is choosing your fabric. It depends on the final look you want for your patch. Some popular options include cotton twill, felt, and denim.

Twill

Twill is a versatile fabric that is most commonly used in the production of custom embroidery patches. It is a durable and long-lasting fabric that can withstand repeated washing and wear.

Twill fabric is made by weaving the fibers in a diagonal pattern, which gives it a distinctive texture and appearance. This texture makes twill patches stand out and gives them a unique look that cannot be replicated with other fabrics.

One of the primary advantages of using twill for custom embroidery patches is its ability to hold up well under intense use. This fabric is often used for patches that will be worn on uniforms or other clothing items that will be subjected to heavy wear and tear. Twill patches are also ideal for use on bags, hats, and other accessories.

Another advantage of using twill fabric is its ease of use. This fabric is easy to embroider, making it an ideal choice for creating intricate designs and details. Additionally, twill fabric is available in a wide range of colors, making it easy to match the fabric to the design.

Felt

Felt is another popular fabric used for custom embroidery patches. It is a soft, fuzzy fabric that provides a unique look and feel to patches. Felt is made from a variety of materials, including wool and synthetic fibers. The texture of felt gives patches a more tactile feel than other fabrics, which can be a desirable characteristic for certain projects.

One of the primary advantages of using felt for custom embroidery patches is its affordability. Felt is typically less expensive than other fabrics, making it an ideal choice for budget-conscious projects. Additionally, felt patches are lightweight and easy to sew onto clothing and accessories.

Another advantage of using felt fabric is its versatility. Felt comes in a wide range of colors and can be cut into various shapes and sizes, making it easy to customize patches to meet specific needs. Felt patches are also often used for decorative purposes, such as on jackets or bags.

Denim

Denim is a popular fabric used for custom embroidery patches, particularly in the fashion industry. It is a durable and rugged fabric that is often associated with jeans and other denim clothing items. Denim patches provide a unique and stylish look that can add a touch of personality to any garment or accessory.

One of the primary advantages for custom embroidery patches is its versatility. Denim comes in a wide range of colors, from classic blue to black, white, and various shades of gray. This makes it easy to match the fabric to the design and create patches that are both stylish and functional.

Another advantage is its durability. Denim is a strong and sturdy fabric that can withstand repeated washing and wear. This makes it an ideal choice for patches that will be used on clothing items or accessories that will be subjected to heavy use.

In a word. Each fabric has its unique characteristics, advantages, and disadvantages. Twill is durable and easy to embroider, felt is affordable and versatile, and denim is stylish and rugged. By considering the specific needs of your project, you can choose the fabric.

Step 2: Choose Embroidered Patch Edge Options

When it comes to choosing edge options for embroidered patches, there are several options to consider. Here are some of the most common edge options:

Scissors

This is a basic edge option where the patch is simply cut with scissors. This edge option is not very durable and can easily fray over time.

Laser cut

This edge option uses a laser to cut the patch, which creates a clean, precise edge. Laser cutting is ideal for complex shapes and designs and is a popular choice for patches that require a high level of detail.

Stitch and cut

This edge option involves stitching around the edge of the patch and then cutting away the excess fabric. This method creates a clean, finished look and is commonly used for patches that will be sewn onto clothing.

Merrow border (overlock border):

This edge option uses stitches from a special sewing machine to create a tight, overlock stitch around the edge of the patch. This creates a durable, finished edge that is commonly used for patches that will be worn on uniforms.

Heat cut

This edge option uses a heat-sealing process to melt the edge of the patch, creating a smooth, finished edge. Heat cutting is ideal for patches that have a simple shape or design and is commonly used for patches that will be ironed onto clothing.

When choosing an edge option for your embroidered patch, consider the design and intended use of the patch, as well as your budget and desired level of durability.

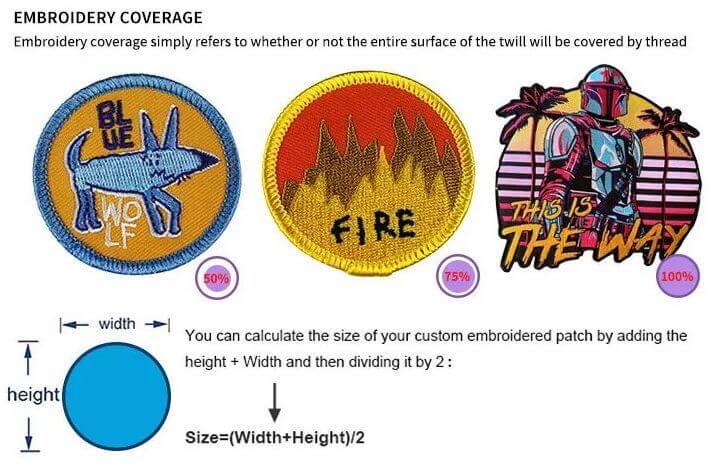

Step 3: Choose patches Size

Choosing the right patch size depends on the specific task or application you are working on. Generally, smaller patch sizes are more effective at capturing fine details, while larger patch sizes are better at capturing broader features.we produce patches from 0.5inch to 10inches.

Step 4: Start Embroidering

Once your embroidery machine is set up, we will start embroidering your patch. we use multi-needle machine, up to 9 thread colors.

Step 5: Finishing Your Patch

Now, the final embroidered patch prepared. we will send to you via express.

III. How to design patches?

IV. How long does it take to manufacture embroidery patches?

The manufacturing time for embroidery patches can vary depending on a few factors such as the complexity of the design, the quantity of patches being produced, and the production method used.

Generally speaking, the manufacturing process for embroidery patches involves several steps, including digitizing the design, selecting the appropriate thread colors, hooping the fabric, stitching the patch, cutting, and applying any necessary backing or adhesive.

For a small batch of simple designs, it may take only a few hours to produce the patches. However, for larger quantities multiple patches or more complex designs, the manufacturing process can take several days or even weeks.

It’s best to consult with a professional embroidery patch manufacturer for an accurate estimate of the manufacturing time based on your specific design and production needs.

V. Suppliers for Embroidered Patches

VI. Final words: You Can Make Embroidery Patches Easily with Professional Results

Pinsfun is a professional manufacturer of custom patches, including custom printed patches, custom woven patches, custom chenille patches, and PVC patches. Quality is our culture. any needs, please fill below forms. our sales person will get back to you ASAP.

DIY Patches: How To Make Your Own Patches For Beginners